Features

Why choose extruded curbs?

1

Quick and Clean

Curbing goes in quickly and cleanly after paving, so as not to impede the progress of your larger project.

2

Cold Weather Installation

We can install an extruded curb in late fall or early winter, even as asphalt plants are closing.

3

Finished Look

Concrete curbing is jointed and broomed as it is placed. This gives parking lots a neat finished appearance, as opposed to precast, nail-down concrete and asphalt extruded curbs.

Anchors and Structure

Anchors and Structure

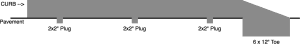

Our curbs are doweled (anchored) into the pavement, asphalt or concrete, approximately 30 inches on center, by drilling 2-inch diameter holes two inches deep. We anchor the tapered ends of the curb into the pavement using a 6″x6″x12″ toe, the width of the curb. As the machine passes of the anchor holes, concrete is forced into the drilled-out space, creating a monolithic plug on the bottom of the curb for structural bonding. Toeing the bare ends of the curb into the pavement gives the curb a toehold for strength and an additional structural bond to the pavement. See our Curb Diagram for a visual representation.

Requirements to Begin Work

All that is necessary for layout work is curb alignment and radius points, as the grade is already established by the top of the pavement.

Cost

The cost of concrete curbing will be determined by the job. For larger jobs, the price per lineal foot will be lower. This includes doweling, toeing, curing and material. Cost is dependent upon project size, amount of radii, number of pieces and corner work.